Views: 321 Author: Site Editor Publish Time: 2025-11-17 Origin: Site

Aluminium extruded profiles are widely used across construction, automotive, machinery, and renewable energy industries. Their popularity comes from aluminium’s lightweight nature, strength-to-weight ratio, corrosion resistance, and—most importantly—its ability to be extruded into highly customized shapes.

For engineers and buyers who work with aluminium extrusion for the first time, many technical terms and design concepts may seem confusing. This guide explains the essential knowledge you need: profile shapes, tolerances, material behavior, and commonly used terminology.

An aluminium extruded profile is a continuous cross-section shape produced by pushing heated aluminium billets through a steel die.

The final shape is determined by the die design and can be simple (angles, channels, tubes) or highly customized based on a CAD drawing.

Typical advantages include:

Consistent shapes along the entire length

Excellent precision

High design flexibility

Cost-effective mass production

Wide choice of surface finishing options

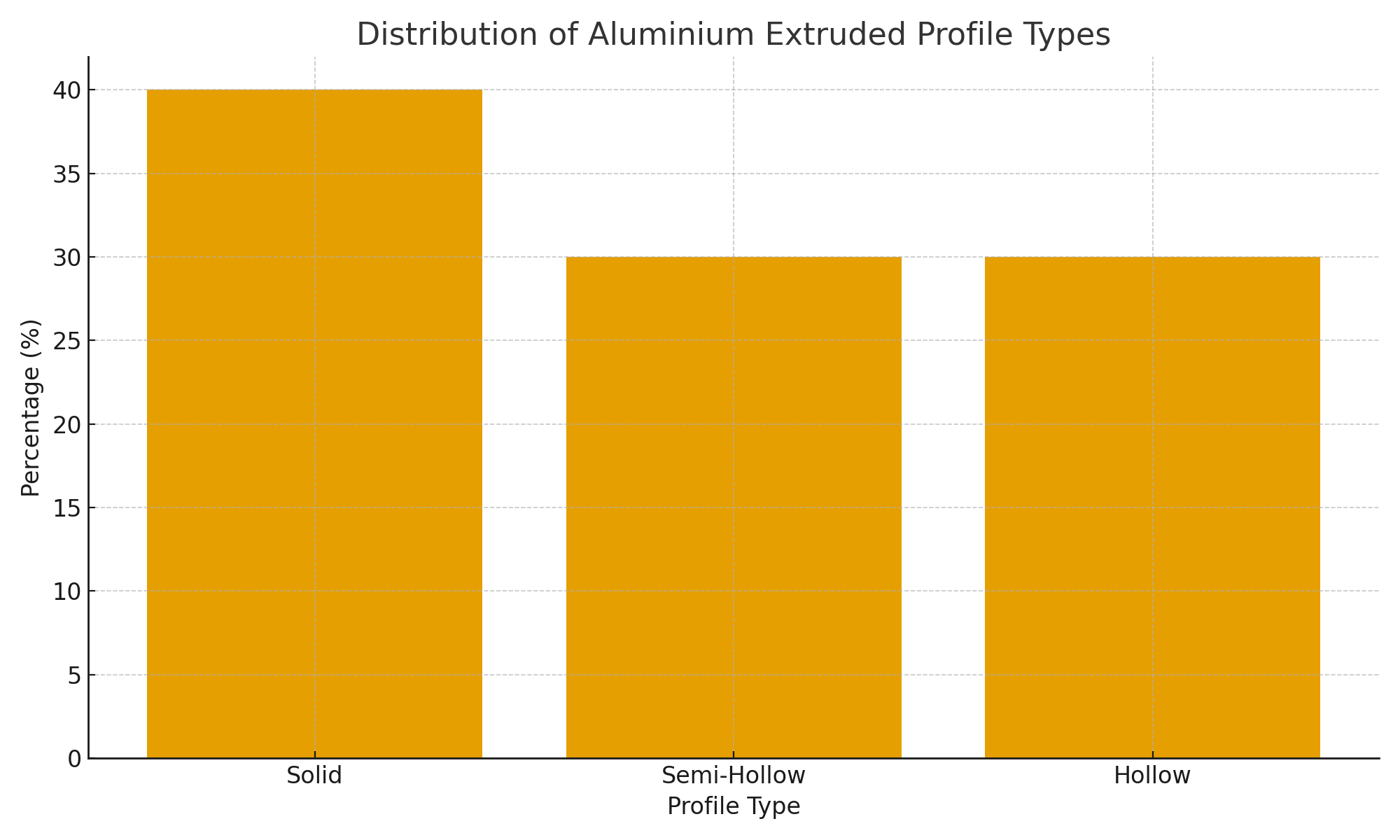

Aluminium profiles can be categorized into several general shapes:

No internal voids.

Used for frames, mechanical parts, brackets, etc.

Partially enclosed shapes with narrow openings.

Used for lighter structural applications.

Fully enclosed voids; round tubes, square tubes, multi-chamber shapes.

Used for lightweight structures, heat transfer applications, and modular systems.

To better understand the overall usage distribution of profile shapes in typical industries, the following bar chart provides a clear comparison:

From the data above, solid profiles remain the most widely used due to their strength and simplicity, while hollow and semi-hollow profiles follow closely because of their strength-to-weight advantages.

Wall thickness directly influences:

Structural strength

Weight

Extrusion stability

Production cost

Uniform thickness and smooth transitions are recommended to improve manufacturability and control tolerance.

Tolerances define acceptable deviations in:

Dimensions

Wall thickness

Straightness

Twist

Flatness

Surface quality

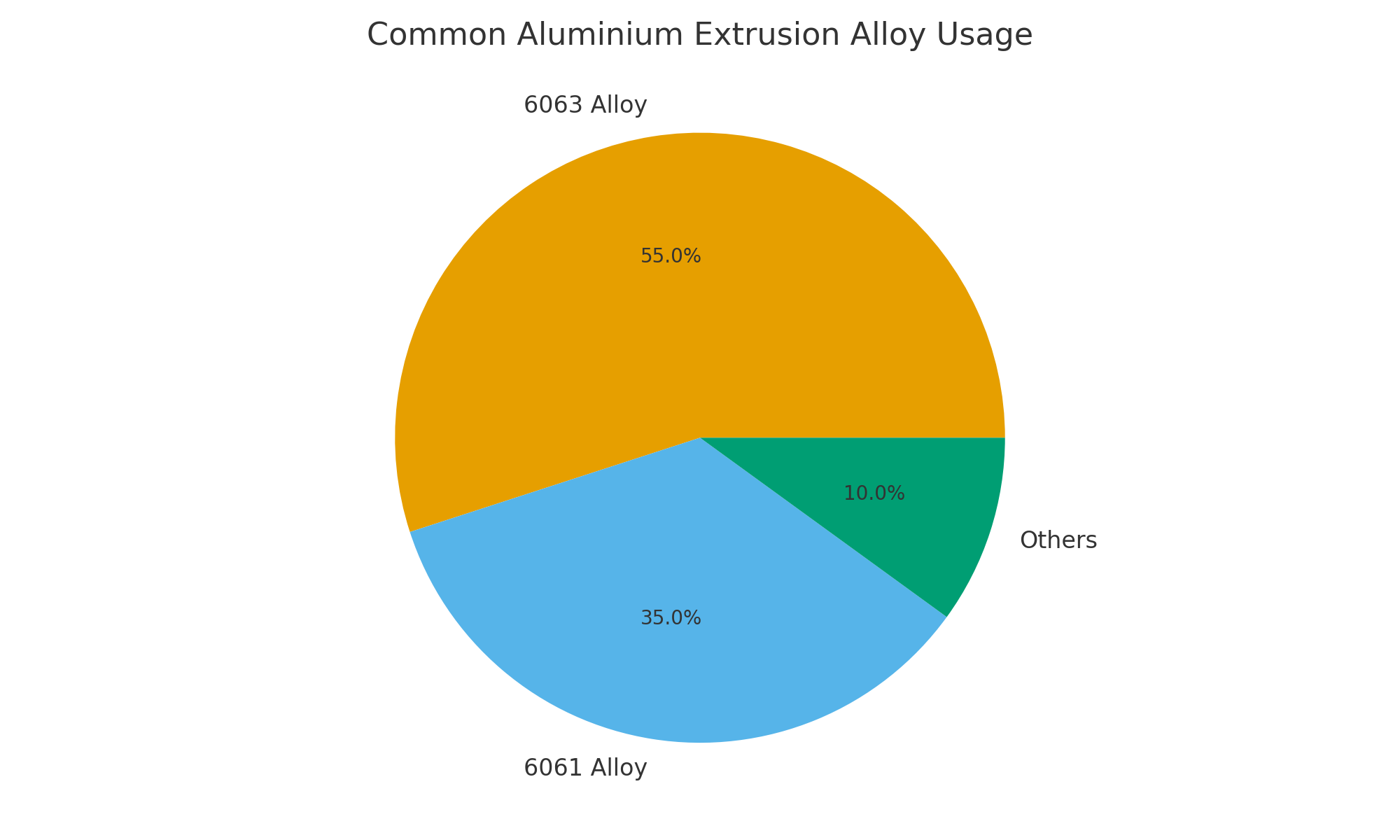

Tolerances depend on shape complexity, alloy choice (6061/6063), and temper (T5/T6).

Extrusion Die — Steel tool that shapes aluminium.

Billet — Heated cylindrical aluminium block.

Alloy 6063 / 6061 — Determine hardness, corrosion resistance, machinability.

Temper T5 / T6 — Indicates mechanical strength after heat treatment.

Profile Length — Typically 3–6 meters.

Surface Finishing — Anodizing, powder coating, sandblasting, etc.

To illustrate how different aluminium alloys are selected in real projects, here is a data visualization:

The chart demonstrates that 6063 alloy is the most commonly used due to its excellent extrudability and finishing properties, while 6061 is preferred for higher-strength applications.

The typical process:

Submit CAD drawing

Engineers evaluate the design

Die design and manufacturing

Billet heating and extrusion

Cooling and stretching

Cutting to length

Optional heat treatment and surface finishing

This workflow ensures high accuracy and stable quality.

Solar panel frames

LED light housings

Heat sinks

Automotive structures

Machine parts

Building façades

Modular rooms and charging stations

Industrial enclosures

Understanding aluminium extruded profile shapes, tolerances, material terminology, and typical alloy usage helps buyers and engineers make accurate decisions when designing custom components. With a proper CAD drawing, nearly any profile can be manufactured to meet structural, aesthetic, or functional requirements.