Views: 0 Author: Site Editor Publish Time: 2025-08-30 Origin: Site

Why do powerful devices stay cool under pressure? Heat sinks make this possible, preventing damage and failure. From CPUs and GPUs to LEDs and power amplifiers, heat sinks are everywhere. Even automotive electronics depend on them for safety and performance.

In this article, you’ll learn essential Heat Sink Design Facts, practical guidelines, and the importance of thermal analysis. We’ll explore different types of heat sinks, design considerations, and industry applications. Finally, we highlight why the Triangle Aluminum Heat Sink offers an efficient solution for modern compact electronics.

A heat sink is a device that moves heat away from hot electronic parts. It often sits on CPUs, GPUs, LEDs, or power transistors. It spreads heat into air or fluid so the component keeps working safely.

Heat sinks protect electronics from overheating. When chips run too hot, they slow down or even fail. A heat sink keeps the temperature lower so the device lasts longer.

Heat moves in three ways. Conduction happens when heat passes through solid contact, such as from a chip to metal. Convection occurs when air or liquid carries the heat away. Radiation happens when heat energy leaves as infrared waves.

Thermal analysis is vital in heat sink design. It shows how heat flows through the sink, fins, and materials. Engineers use it to predict hot spots, airflow issues, and performance limits before building the real part.

| Method | How It Works | Example Use |

|---|---|---|

| Conduction | Heat passes through direct contact | Chip touching the base of heat sink |

| Convection | Heat carried by moving air or fluid | Fan blowing across fins |

| Radiation | Heat leaves as infrared energy | Heated surface releasing energy |

One of the most overlooked Heat Sink Design Facts is that poor contact surfaces reduce conduction efficiency. Even small air gaps reduce performance dramatically, which is why TIM is essential.

A passive heat sink works by natural convection. It has no fans or pumps, so air moves slowly across its fins. They are silent and reliable since nothing mechanical can fail. They also save energy because they use no electricity. The downside is clear. In high-power devices, passive cooling often cannot remove heat fast enough.

Passive sinks are common in routers, LED lamps, and low-power chips. They are also used in space-constrained devices where reliability is more critical than maximum cooling.

An active heat sink uses forced convection. It often has a fan or pump that drives air or liquid across the fins. This makes it more effective at pulling heat away. They cool faster and handle higher power loads. But the tradeoffs matter. Fans make noise, consume power, and sometimes break down.

In server farms, active air cooling is essential to prevent downtime. Liquid-cooled active sinks are also used in gaming GPUs and data centers, where heat loads exceed what passive systems can handle.

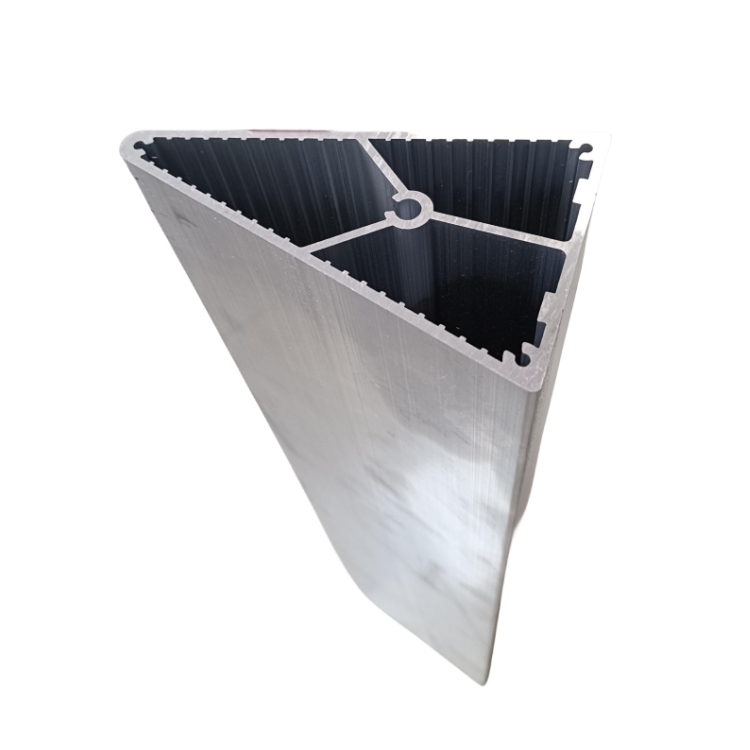

The Triangle Aluminum Heat Sink looks different from flat fin designs. It uses angled fins shaped like triangles to increase surface area. This shape helps guide airflow smoothly and reduces resistance. It is often made from aluminum since the metal balances cost and conductivity.

Why choose this design?

Extra surface area for better heat spreading

Angled geometry improves airflow direction

Compact structure fits small electronics or LEDs

This geometry is especially useful in LED bulbs, where space is limited. A triangular fin arrangement spreads heat evenly while maintaining small size.

When reviewing the most important Heat Sink Design Facts, engineers focus on several key aspects. These include thermal resistance, material selection, fin geometry, surface treatments, and the role of thermal interface materials. Each factor influences how effectively a heat sink manages heat flow and ensures system reliability.

Thermal resistance measures how easily heat flows through a system. It matters because every watt of power adds temperature rise.

If resistance is too high, devices overheat quickly. A heat sink lowers thermal resistance and keeps chips within safe limits. For instance, a CPU generating 95W may require a sink with less than 0.5 °C/W to remain safe.

Material choice changes how well the sink performs. Aluminum is common since it is cheap, light, and easy to shape. Copper works better at conducting heat but is heavy and expensive. Graphite foam is light and strong, but fragile and costly.

Aluminum dominates because it balances price and performance. A Triangular Fin Heat Sink is a good example. It uses less material but still spreads heat efficiently.

Fins give the sink more surface area. The bigger the surface, the more heat leaves. Straight fins are simple and cheap. Pin fins allow air to move in many directions. Circular fins spread air evenly. Triangle-profiled fins add contact space and guide airflow better.

Some Heat Sink Design Facts show that beyond a certain point, adding more fins reduces performance due to airflow blockage. Optimizing spacing is more effective than maximizing quantity.

Surface finish improves performance. Anodized aluminum has higher emissivity, so it radiates more heat. Black coatings also help by increasing infrared emission.

While convection dominates heat transfer, coatings still lower peak temperatures by a few degrees. For designs near the limit, coatings can be the difference between reliability and failure.

Between the chip and the base of the sink, tiny air gaps block heat. TIM fills those spaces. It may be paste, grease, or pads. Without TIM, even the best sink loses efficiency.

Correct application is a guideline engineers cannot ignore. Uneven layers reduce efficiency. Industry tests show poor TIM use can increase temperatures by 10–20°C.

Thermal simulation is one of the most important steps in modern heat sink design. It allows engineers to study how heat travels through components before any hardware is built. By running simulations, they can predict hot spots, airflow bottlenecks, and areas of poor thermal contact. This early insight prevents costly redesigns and helps ensure that final products operate within safe temperature limits.

Overheating is a silent threat that shortens device life. CPUs throttle when hot, reducing performance. LEDs gradually lose brightness and shift color when heat builds up. Power amplifiers and transistors risk thermal runaway, which can lead to sudden failure. Heat sinks slow these issues, but only if designed with accurate analysis.

Thermal simulation provides a virtual testing ground. Engineers can compare different materials, fin designs, and coating methods without producing physical prototypes. This reduces development costs, accelerates innovation, and extends product lifespan by delivering more reliable cooling solutions.

Hand Calculations – Quick estimates using formulas.

CFD (Computational Fluid Dynamics) – Simulates airflow, turbulence, and heat transfer. Engineers test designs like an Angled Aluminum Heat Sink virtually.

FEA (Finite Element Analysis) – Divides a sink into elements to predict heat transfer in detail.

Comparison of Methods:

| Method | Accuracy | Cost | Use Case |

|---|---|---|---|

| Hand Calculation | Medium | Low | Early design checks |

| CFD Simulation | High | Medium | Airflow optimization |

| FEA Simulation | Very High | High | Complex structures, materials |

Ambient Temperature & Airflow: Hot rooms increase device temperature; airflow strongly affects cooling.

Material Conductivity: Aluminum is common, copper spreads faster but costs more, graphite foam is light but fragile.

Contact Resistance: TIM reduces gaps and improves heat transfer.

Heat Transfer Path:

Chip (heat source)

TIM (paste or pad)

Heat Sink Base (metal plate)

Fins (surface extension)

Airflow (removes heat)

Use a Compact Triangle-Shaped Heat Sink for tight enclosures.

Ensure airflow: fins vertical, spacing adequate, vents present.

Reapply TIM regularly as paste dries or pads wear out.

Combine passive sinks with fans for hybrid cooling.

Cooling Method Comparison:

| Method | Advantage | Limitation | Best Use Case |

|---|---|---|---|

| Passive | Silent, energy efficient | Limited heat removal | Low-power devices |

| Active | Stronger cooling | Noise, power usage | GPUs, CPUs |

| Hybrid | Balanced performance | More complexity | Servers, compact gear |

To create efficient heat sinks, engineers should:

Select materials that balance conductivity, cost, and weight.

Use thermal analysis to check early designs.

Optimize fin spacing and geometry for airflow.

Apply surface treatments to increase emissivity.

Reapply TIM during maintenance cycles.

Combine passive and active methods when loads vary.

Choose compact designs like a Heat Sink with Triangular Fins for small enclosures.

These guidelines provide a roadmap for effective cooling solutions and complement the essential Heat Sink Design Facts engineers must remember.

Even experienced designers overlook some critical points:

Ignoring airflow direction – placing fins horizontally reduces convection efficiency.

Overcrowding fins – too many fins reduce overall cooling.

Skipping thermal analysis – relying only on intuition often leads to failure.

Poor TIM application – inconsistent coverage creates hot spots.

Wrong material choice – copper improves conduction but may cause weight problems in portable devices.

Recognizing these mistakes is part of understanding real-world Heat Sink Design Facts.

Heat sinks prevent throttling and enable overclocking. Gamers rely on aluminum sinks with fans for stable performance. In data centers, thousands of CPUs run side by side, and efficient cooling ensures uptime.

They release heat while switching. Heat sinks prevent runaway by spreading energy across surfaces. Industrial equipment often uses massive extruded sinks to handle large currents safely.

LEDs lose brightness without cooling. Designers use aluminum sinks for low cost. A Heat Sink with Triangular Fins maximizes surface area in bulbs and panels. This ensures LEDs maintain consistent brightness and color quality.

EV batteries generate heat during charging. Heat sinks and liquid plates regulate temperature, extending battery life. Automotive systems also cool inverters, chargers, and onboard computers. Without proper management, batteries risk thermal runaway, which can cause fires.

Industry Overview:

| Industry | Component | Heat Sink Role |

|---|---|---|

| Computing | CPUs, GPUs | Prevent throttling |

| Electronics | Amplifiers | Avoid thermal runaway |

| Lighting | LEDs | Maintain brightness, extend life |

| Automotive | EV batteries | Manage heat, improve safety |

Heat sink design is vital for safe electronics. Thermal analysis prevents overheating and extends component lifespan. By understanding Heat Sink Design Facts and applying proper guidelines, engineers can build efficient cooling systems. The Triangle Aluminum Heat Sink remains a smart choice, offering cost balance, compact size, and performance for modern devices.

A: It removes heat from components and keeps devices safe.

A: It predicts heat flow, prevents overheating, and extends device lifespan.

A: Its angled fins increase area, improve airflow, and save space.

A: Aluminum is light and cheap; copper conducts better but is heavier.

A: Reapply every 2–3 years, depending on system use.

A: Yes, hybrid systems balance silence, power use, and performance.